Valmet OptiWrap roll wrapping and handling

For essential roll protection and smooth production flow

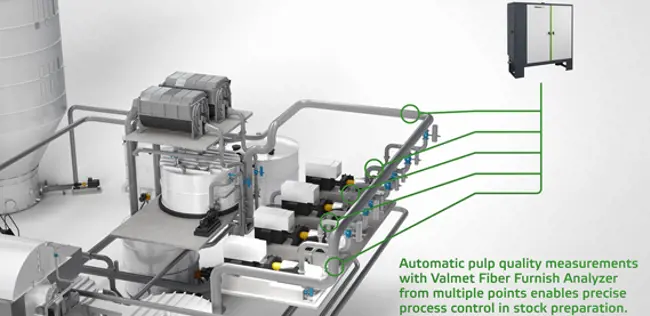

Valmet and Pesmel have a broad cooperation agreement where Pesmel acts as Valmet’s exclusive contract supplier in roll handling, packing, and storing technology. Pesmel takes full responsibility for Valmet’s roll handling and packing systems, R&D, manufacturing, and system deliveries. Valmet continues roll handling and packing systems sales as part of its project sales under the Valmet brand. Pesmel also sells Valmet products as part of its project sales through its own sales channels under the Pesmel brand.

Want to talk to our board & paper experts?

If you wish to get further information like technical specifications or details, need a quotation, or wish to discuss different solutions, fill in the contact form and our experts will contact you shortly.

Contact our expertsOptiWrap Multi - three high-capacity solutions

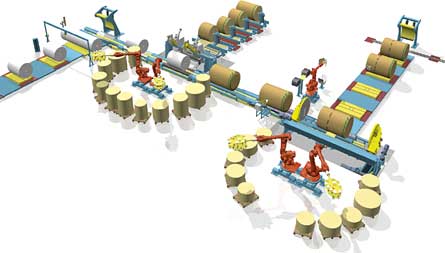

OptiWrap high-capacity multistation wrapping machine

- Fully automated multistation wrapping system with the best wrapping performance around and a capacity of 180 rolls/hr.

- The highest capacity on the market

- High reliability and availability

- Head pick-up directly from pallets or revolvers

- Continuous wrapping principle; no downtime due to material replenishment

- Onesider solution available

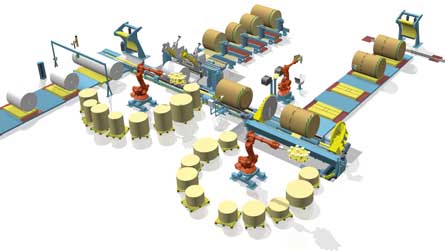

OptiWrap indexing multistation wrapping machine

- Reliable, proven wrapping technology and full automation.

- Suitable for 80–120 rolls/hr.

- Fast electrically powered and controlled roll movement

- Three backstand alternatives available

- Head pick-up directly from pallets or shelves Heads remain on standard shipping pallets on the floor; rough pallet placement is done by the operator; exact head placement by a robot

- Onesider solution available

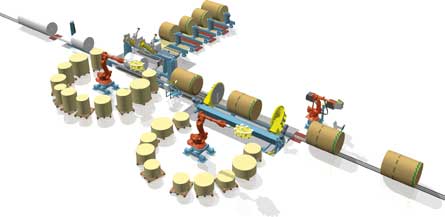

OptiWrap conveyor multistation wrapping machine

- The wrapping process takes place along the winder discharge conveyor. Fully automated multi-station system with a capacity of 100 rolls/hr.

- Space-saving layout

- Highly cost-efficient

- Semi- or fully automated

- Three backstand alternatives available

- Onesider solution available

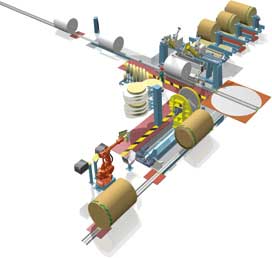

OptiWrap Single – for lower-capacity solutions

- This semi-automated wrapping system is ideal for mills with low or medium capacities and restricted floor space. It can wrap up to 50 rolls/hr.

- Compact layout

- Safe operation

How to plan a successful rebuild?

Rebuilding a paper or board machine can improve the competitiveness of your business and your processes. But where do you start? Download our e-book to learn how to develop a winning rebuild concept, how to minimize rebuild related risks, and how to ensure smooth ramp up to full production.

Download e-book